The Technical Necessity of Scheduled Maintenance in Mechanical and Quartz Movements of High-End (and Not Only) Watchmaking

The operation of a watch - especially one in the high-end category - relies on precision micromechanical systems, where any deviation in lubrication, friction or tolerances directly affects torque, amplitude and overall chronometric stability. Maintenance every 6–7 years is a documented practice recommended by all major manufacturers (Rolex, Omega, Breitling, IWC, JLC, etc.), as it addresses the natural wear of the movement.

1. Lubricant Degradation and Its Impact on Performance

Specialized synthetic lubricants have specific chemical stability. After 5–7 years they begin to:

- oxidize,

- change viscosity,

- create solid residues,

- migrate away from the jewels.

This increases friction on wheel pivots, affecting:

- the torque within the gear train,

- the amplitude of the regulating organ (balance),

- isochronism.

A reduction of amplitude below specification (for example, <200° crown-down on a timing machine with the movement half-wound) is a clear indication that a full overhaul is required.

2. Wear of Key Components in Mechanical Movements

Escapement System

- Wear on the pallet-fork jewels due to insufficient lubrication.

- Lubrication failure on the escape wheel.

- Increased energy losses, resulting in lower amplitude.

Mainspring and Barrel

- Aging of the mainspring and loss of elasticity.

- Micro-wear on the barrel arbor and barrel wall.

- Reduced torque stability causing issues with power reserve and timekeeping accuracy.

Gear Train

- Wear on pivots and jewels.

- Accumulation of old lubricants, resulting in increased transmission resistance.

Balance Wheel

- Deformation or changes in the hairspring’s behavior (coil deformation).

- Suboptimal oscillation of the balance staff / shock protection system (Incabloc, KIF, Paraflex).

3. Quartz Movements – Specialized Issues

A quartz movement is not a simple mechanism; it is an electromechanical system that also requires maintenance.

Stepping Motor

- Wear on the magnetic rotor and stator.

- Failure in the correct switching of magnetic pulses, leading to skipping seconds.

Gear Train

- The same micromechanical friction issues as in mechanical movements.

- Loss of lubricants increases the load on the step motor, resulting in higher battery consumption.

Circuit Board

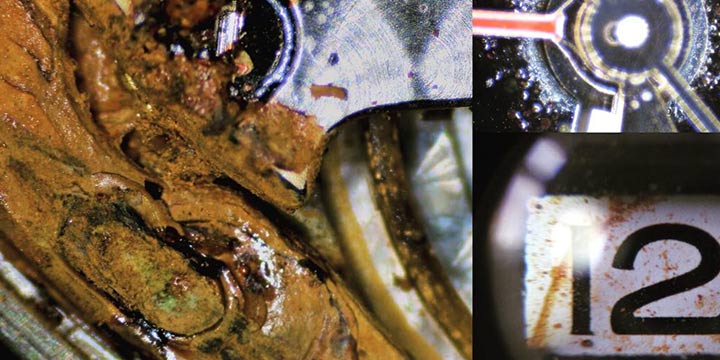

- Sensitivity to moisture, oxidation and potential battery leakage.

- Damage is often non-repairable, requiring full movement replacement.

Batteries

- Electrolyte leakage, causing oxidation of contacts, coils and other components.

- Risk of total movement destruction if left unchecked for years.

4. Water-Resistance – Gaskets (O-Rings) & Waterproof Testing

Gaskets made of neoprene or fluorocarbon:

- lose elasticity over time,

- develop micro-cracks,

- no longer ensure proper sealing.

This can lead to:

- moisture ingress (condensation),

- oxidation of components,

- damage to bridges, hands and dial,

- corrosion of the main plate.

Every overhaul must include:

- replacement of all gaskets,

- waterproof testing,

- vacuum testing.

5. Full Overhaul Procedure

A proper complete maintenance service includes:

- Full disassembly of the movement.

- Cleaning of all components in cleaning - ultrasonic machines with specialized solutions.

- Inspection for wear.

- Replacement of worn components with genuine parts.

- Reassembly.

- Lubrication with the correct lubricants in precise quantities.

- Timing, amplitude and beat-error checks using professional timing machines.

- Final regulation in multiple positions.

- Vacuum and waterproof testing.

- Final 5-day quality control.

6. Economic and Technical Consequences of Delayed Maintenance

Delaying maintenance leads to:

- increased wear on jewels, escapement, power-delivery systems,

- mandatory replacement of high-cost components,

- extended labor time due to more severe damage,

- possible lack of spare parts for discontinued movements.

Technically, a movement that runs for years without service may:

- drop below 200° amplitude,

- show beat error >0.8 ms,

- fail to maintain power reserve within specifications - tolerances,

- operate with excessive friction that permanently damages wheel pivots.

Conclusion

A 6–7 year service interval is not an “exaggeration” but a technically justified necessity. Precision micromechanisms require stable lubrication, controlled friction, proper sealing and preventative wear control.

A well-maintained movement:

- keeps amplitude and isochronism within specification,

- minimizes component wear,

- remains reliable, accurate and durable for decades.

Preventative maintenance is far more economical than extensive repairs and protects the original investment, ensuring the watch performs as it was designed to.